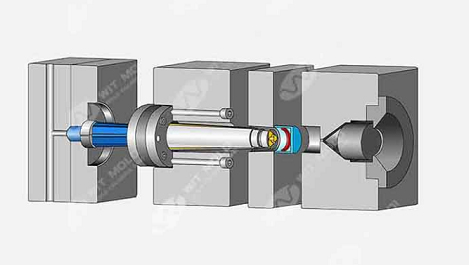

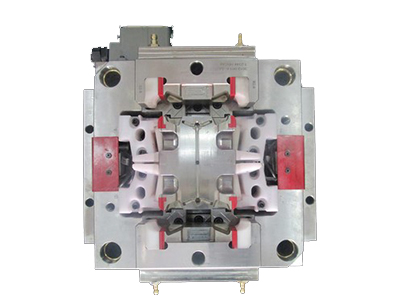

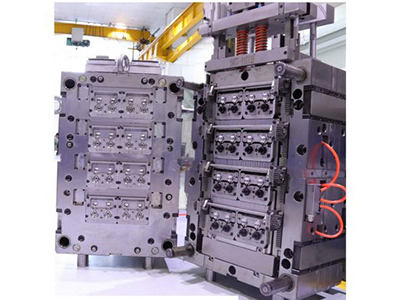

Collapsible Core Molds

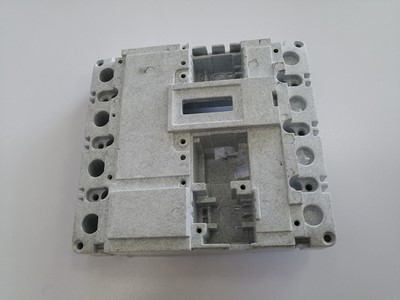

Collapsing cores allow a part with large threads, long thread runs or undercuts to be ejected from the cores with just a stripper plate. Various types of collapsing cores are available from spring loaded to dove tail designs. Cooling time can be reduced on many applications since the core is separated from the part before ejection, minimizing the chance for distortion. Overall mold sizes can be reduced as well when unscrewing racks and cylinders are not needed.