Quality Assurance

WIT MOLD is committed to fulfilling or exceeding our customer’s expectations by providing the highest quality products and services. To meet rigid standards of excellence, we adopt integrated quality management system coupled with "Three Inspections" process.

At WIT MOLD we made a firm commitment to quality assurance at every stage of our manufacturing process. We assure the quality by staying up to date with our 16 specific standards and regulations throughout all critical steps from RFQ (Request for Quotation) to delivery.

16 Specific Standards & Regulations

- Sales: Clear and accurate communication;

- Design: Creative ideals; Feasibility verification; Detail inspection;

- Drilling: Proper cooling & lubrication; Prompt chip removal;

- Heat treatment: Reliable supplier; Heat treatment reports;

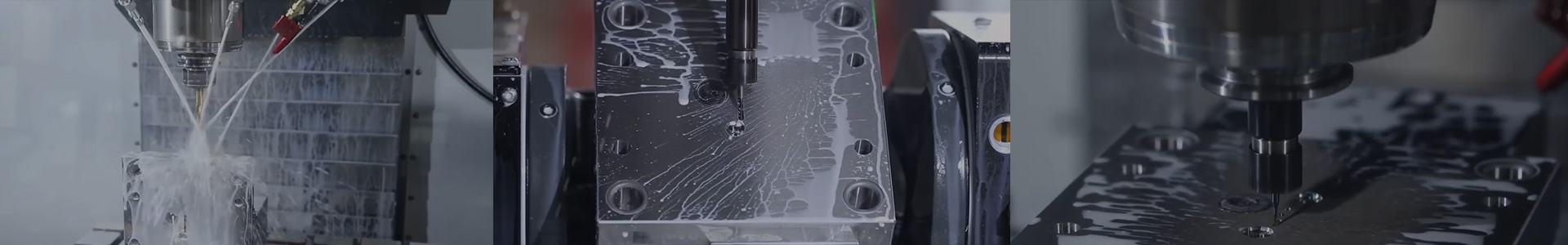

- CNC Machining: Cutter checking; Self inspection;

- Wire cutting: Program checking; Careful inspection;

- EDM: Optimized parameters; Correct data input;

- Polishing: Professional skills; High quality tools;

- Mold Assembling: Precise fitting; Craftsmanship;

- Procurement: Qualified vendors; Traceable records;

- Project management: Technical coordination; Drawing revision confirmation;

- Mold trial: Resin study; Optimized process settings;

- Mould storage: Organized placement; Clear mold identification;

- Quality Control: Incoming inspection; Final inspection; 3 inspections system;

- Package: Good material; Proven methods;

- Shipping: Credible forwarder; Instant updates; POD tracking;